The Challenge: Get a Scrap Yard Running in Less Than a Month

A scrap yard owner in Central Florida had just leased a new location and needed to start hauling loads of metal within 30 days. The problem?

- Their truck scale was old and in poor condition.

- Other companies said it couldn’t be rebuilt.

- New truck scales had a 16–24 week lead time.

We knew we could make it happen.

The Equipment: An Out-of-Production “First Weigh” Scale

The scale was an older First Weigh model, originally manufactured in Sanford, Florida. Rights to the design had been purchased by Emery-Winslow, but none of the original components were still in production.

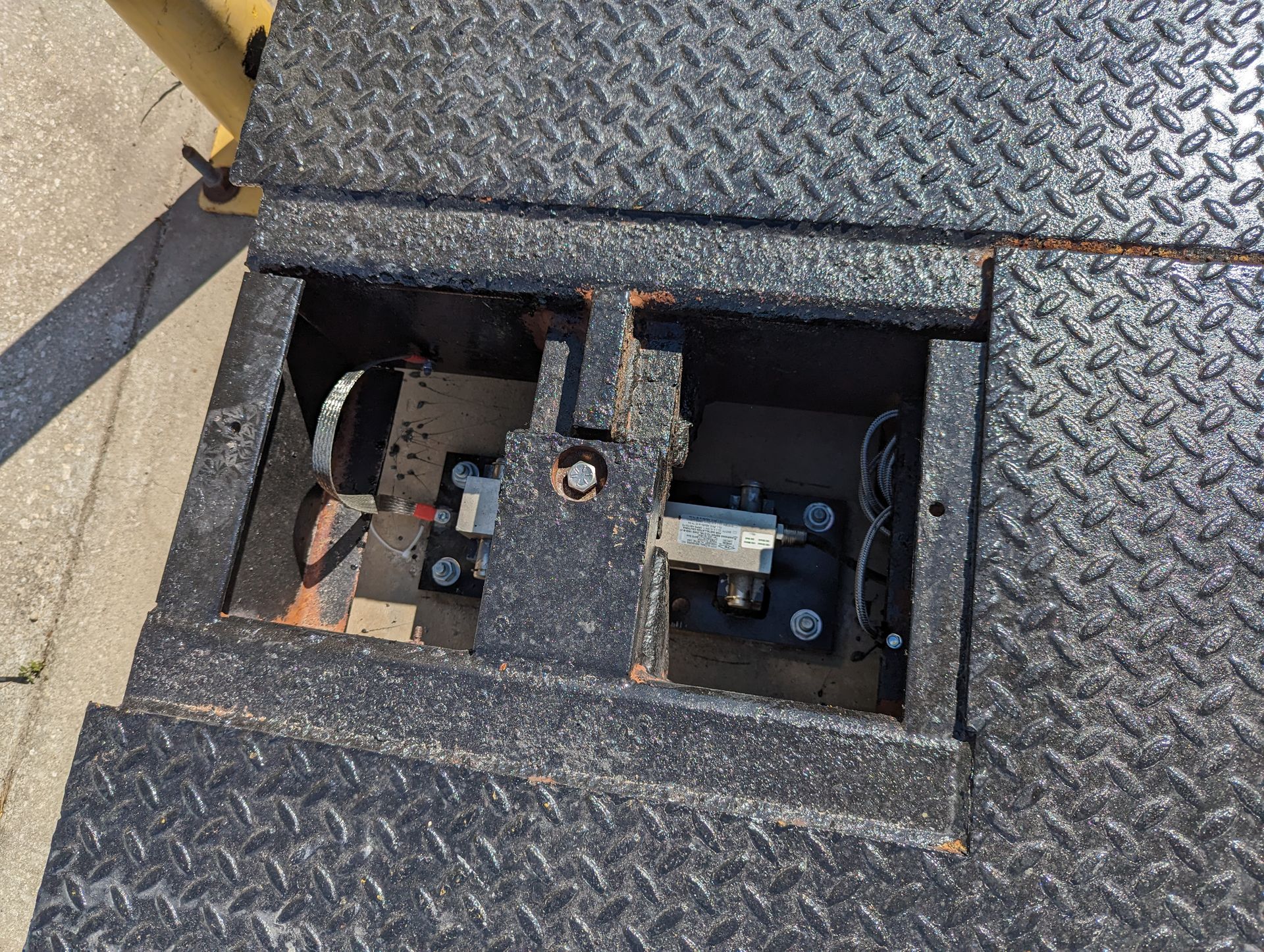

The main problem:

- Severely deteriorated load cell stands under the scale deck.

- Unsafe to leave in service.

Reverse Engineering the Load Cell Stands

We salvaged the two best stands and brought them back to our shop to reverse engineer. These were from a First Weigh using older Epelsa 50K double-end beam load cells, also known as the First Weigh LC32.

The good news? Compatible load sensors — COTI CG-STR 50K — were still available from one of our suppliers.

Within three weeks, a local CNC shop cut, welded, and finished brand-new load cell stands to our exact specifications.

Preparing the Scale for Reassembly

While waiting for the stands, we advised the customer to:

- Clean and reinforce the truck scale deck

- Paint exposed areas to protect against further corrosion

We also inspected the foundation’s critical checking elements. At some point, the scale had been struck by a large tracked vehicle (likely an excavator), bending the side checking stands.

A combination of hydraulic tools and some well-placed sledgehammer strikes got them back into alignment.

Installing the New Load Cell Stands

Once the stands were welded, painted, and fitted with hardware:

- We moved the scale decks back into the foundation.

- Aligned and bolted the deck plates into place.

- Installed the new stands and grounding straps.

Pulled wires through new conduit tubing in the deck.

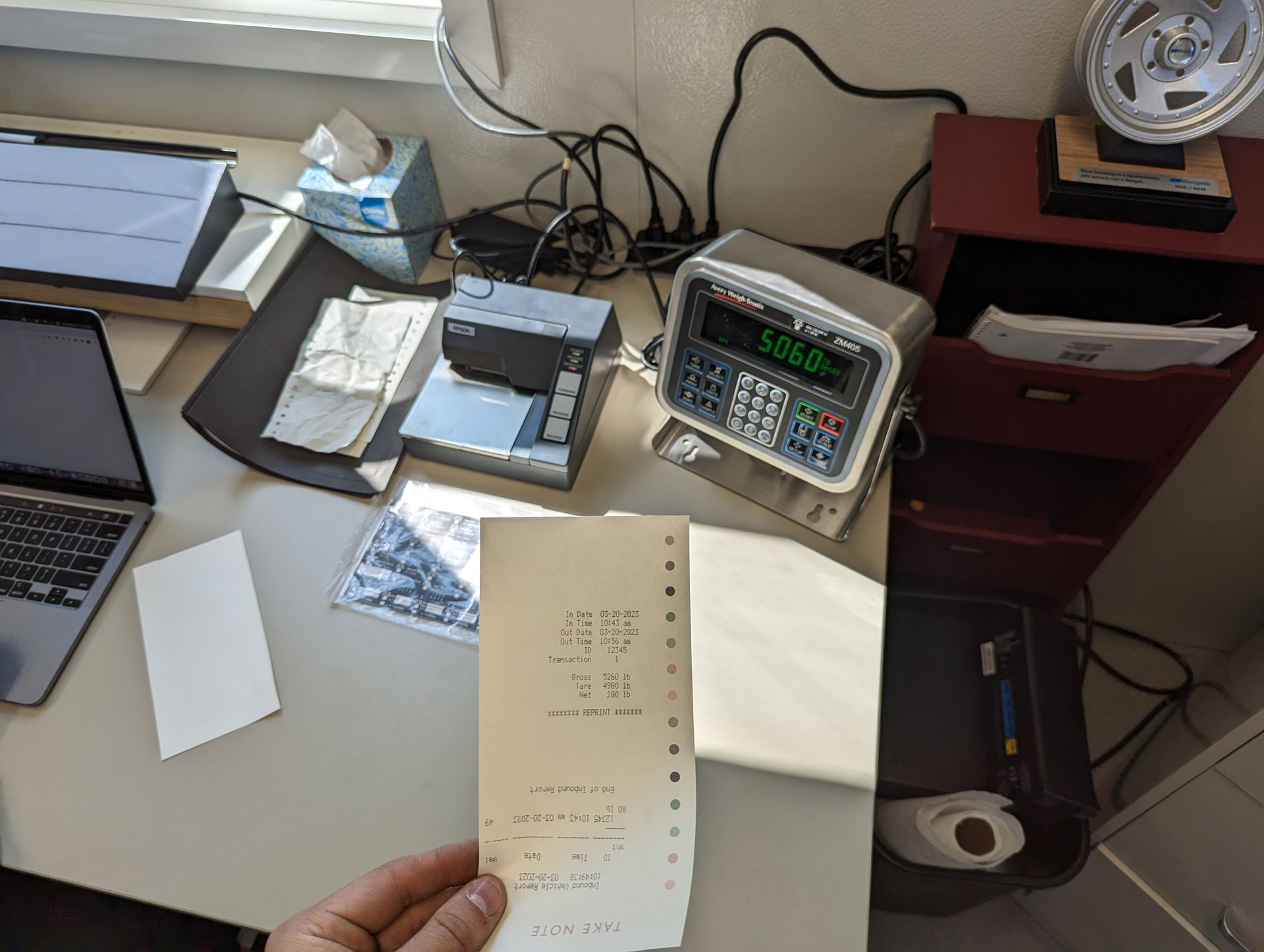

Upgrading the Display and Ticketing System

We equipped the rebuilt scale with:

- A remote weight display positioned for drivers to see

- A digital indicator with a truck in/out database

- An EPSON TM-U295 impact receipt printer for net weight tickets

The system stores full and empty truck weights, calculates the net load, and can connect to PC software for digital weight transmission.

The Result: Mission Accomplished

In less than a month, we:

- Rebuilt an out-of-production truck scale

- Installed new load cell stands and load sensors

- Upgraded the display and ticketing system

- Avoided months-long lead times and the cost of a brand-new scale

When other companies say “it can’t be done,” they might be protecting their bottom line — not your best interests. At Peninsula Scale, we deliver creative, cost-effective solutions that keep your business moving.