Why Hygienic Weighing Matters in Meat Processing

In meat processing facilities, scales operate in harsh, wet, and sanitized environments every single day. To maintain compliance with USDA, FDA, SQF, or BRC standards, your weighing equipment must be:

- Durable under high-pressure washdowns

- Accurate for consistent portioning and batching

- Designed for easy cleaning to prevent contamination

One of the best solutions for these environments is the hydrostatic load cell — a rugged, mechanical weighing technology that can maintain accuracy for many years compared to standard electronic load cells.

Hydrostatic Load Cells: Built for Washdown Environments

Hydrostatic load cells use a mechanical rocking column to absorb misalignment and vibration from mixers, grinders, and blenders. They can last 8+ years with proper care, even under daily sanitation cycles.

Example:

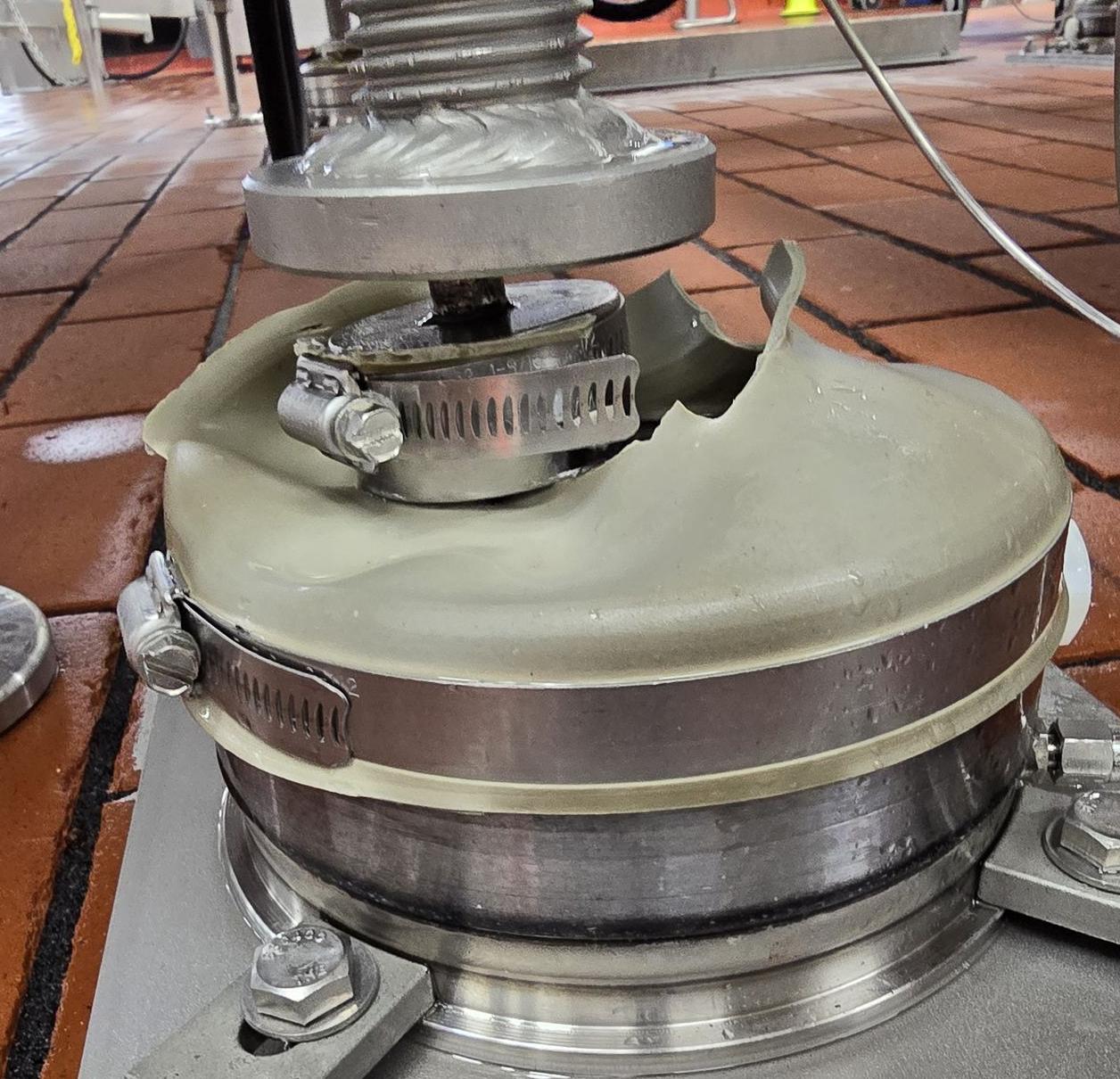

We recently serviced a deli salad manufacturer producing egg, potato, and tuna salads. Their hydrostatic load cell had a rubber boot that:

- Prevents food particle buildup in the mechanism

- Protects the internal rocker pin from contamination

- Maintains hygienic seals during operation and cleaning

After nearly eight years, the boot had worn out and failed — but replacing it was quick and inexpensive compared to swapping an entire electronic load sensor.

Signs Your Hydrostatic Load Cell Needs Service

During inspection, we found:

- Torn boot – An obvious sign of wear

- Bulging boot – Indicates water is trapped inside during washdown, creating internal pressure and potential contamination risk

- Worn rocker pin – Can lead to weighing inaccuracies if not replaced

Replacing the rocker pin and boot, then applying food-safe grease, restored the scale to like-new performance.

The Cost Advantage Over Electronic Load Cells

Hydrostatic load cells offer meat processors:

- Lower lifetime cost – Component-level repairs instead of full load cell replacement

- Superior durability – Resistant to water ingress and washdown damage

- Extended service life – 8+ years between major repairs with proper maintenance

Protecting Accuracy in High-Vibration Applications

In meat processing, mixers, tumblers, and grinders create constant vibration. If weighing components aren’t in top condition, batching accuracy can suffer — affecting both yield control and regulatory compliance.

Regular inspection and timely replacement of boots, pins, and seals ensures your portioning scales, batching systems, and mixing vessel scales stay accurate for years.

📞 Contact Peninsula Scale today for an estimate on calibrating, repairing, or upgrading your washdown-ready scales. We help meat processors keep equipment accurate, compliant, and built to last.