Why Floor Scale Calibration Matters

At first glance, calibrating a floor scale might seem straightforward. But in reality, there are critical nuances that only a trained technician will know — and those details can make the difference between a scale that passes inspection and one that causes costly errors.

Our approach to floor scale service goes beyond adjustments. We find and fix the root cause of your scale issues, ensuring long-lasting accuracy and reduced downtime.

The Anatomy of a Warehouse Floor Scale

A typical floor scale includes:

- Steel or stainless steel deck

- Four load cells (one in each corner)

- Adjustable leveling feet for each load cell

- Junction/summing box inside the deck where load cells connect

- Cable from junction box to the digital weight display (indicator)

Common Floor Scale Problems We Solve

1. Uneven Corner Readings

We place 500 lbs of NIST-certified test weights in each corner to ensure all load cells are balanced. If one corner is off, it may be due to:

- Loose or broken load cell mounts

- Bent leveling feet from forklift damage

- Worn ball-and-cup foot assemblies

Example: A customer’s scale was reading inconsistently depending on pallet placement. We found a load cell mounting block had come loose, re-welded it, rebalanced the corners, and recalibrated — no replacement parts needed.

2. Scale Deck Touching Other Surfaces

If the deck touches a wall, pallet rack, conduit, or debris, readings will be inaccurate. Common fixes:

- Remove debris (pallet wood, dirt) under the deck

- Adjust leveling feet to ensure proper clearance

- Reposition the scale to prevent contact point

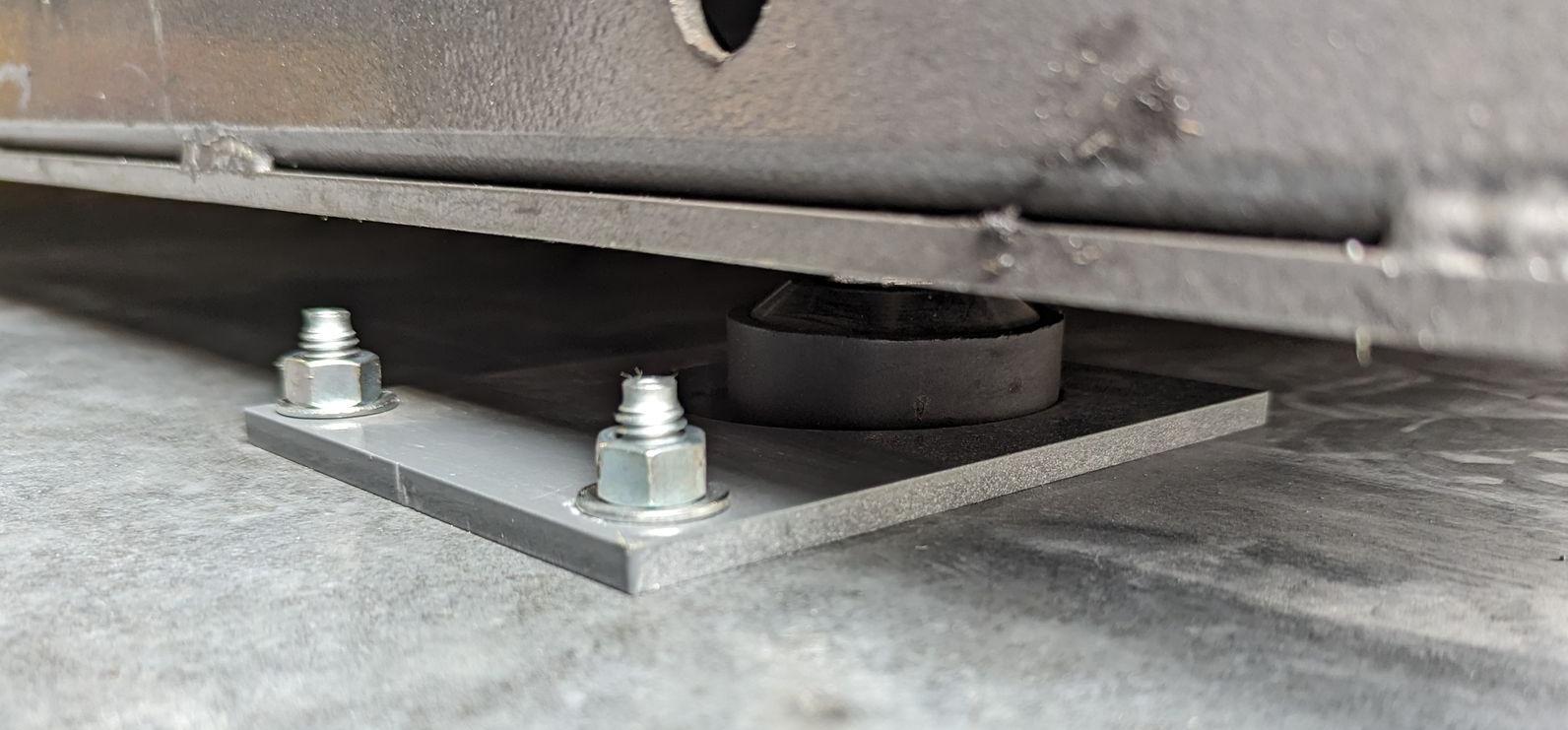

3. Scale Movement Around the Warehouse

Forklift bumps or pallet loading can slowly shift a floor scale until it hits a wall — throwing off readings and risking re-weigh fees from freight carriers.

Our solution: Anchor foot retainers that capture all four leveling feet, preventing movement without causing weighing interference.

4. Unstable or Drifting Weight Readings

Weight fluctuation is often caused by:

- Damaged cables

- Loose connectors or terminal blocks

- Water intrusion in outdoor scales

Example: On a pallet wrapper scale, a loose connector caused wild weight fluctuations whenever the wrapper moved. We hardwired the connection, and the problem disappeared.

In the image above the forklift operator knocked the scale off of the area it was on and the cable was smashed and cut by the fork. The customer called that afternoon and we were onsite at 6am getting it going for them the next morning.

5. Hydrostatic Floor Scales

We also service Emery Winslow Hydrostatic floor scales — which use hydraulic pressure instead of electronics. Ideal for washdown areas, these systems require specialized service for:

- Diaphragm replacements in load sensors

- Tubing, fitting, and pump repairs

- Pressure calibration for accuracy

Our trucks carry the specialized parts and tools to repair hydrostatic systems on the spot

Here is the diaphragm replacement on the load sensor:

Calibration Standards That Meet Legal Requirements

Not all calibrations are equal. For a 5,000 lb capacity scale, the legal-for-trade minimum test weight is 12.5% of capacity (625 lbs). We routinely test with 2,000 lbs of NIST-certified weights to ensure compliance and accuracy.

Why Choose Peninsula Scale

- Full-service calibration & repair for electronic and hydrostatic floor scales

- NIST-certified test weights on every service truck

- Root cause repairs for lasting results

- Emergency service to minimize downtime

📞 Call us today to schedule your floor scale calibration or repair — and get accurate, reliable weighing that lasts.