This can't be right?

Is Your Scale Service Provider Working in Your Best Interest?

At Peninsula Scale, we’re often called in to verify the work of other calibration companies — and sometimes, what we find is alarming.

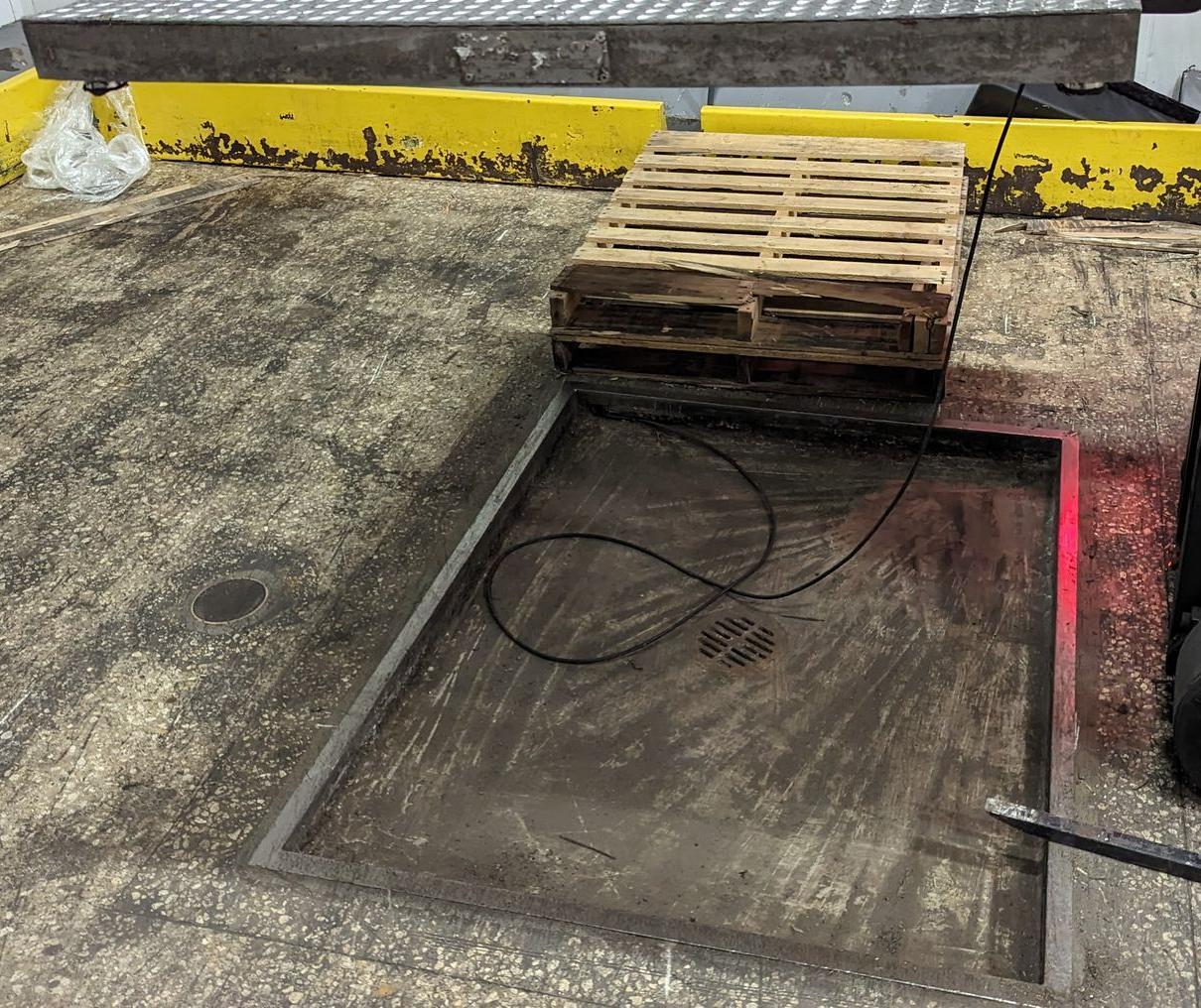

Recently, a customer asked us to re-inspect a stainless steel floor scale that had been “serviced” only three months earlier. From the moment we arrived, the warning signs were obvious.

The First Red Flags

- Debris and neglect – Large chunks of pallet wood were wedged between the edges of the scale platform.

- Poor maintenance – The scale pit was filled with dirt, plastic, and grime that clearly hadn’t been removed in years.

What we thought would be a quick calibration check quickly turned into a deep dive.

Lifting the Scale and Finding the Real Problem

Using a pry bar, we lifted the floor scale out of its pit for a thorough inspection. The issues were worse than expected:

- Wrong capacity – The scale was rated for 5,000 lbs, yet forklifts routinely drove over it to drop pallets in the area.

- Structural failure – The deck was bent, welds had popped, and the thin metal webbing was stretched from repeated overloading.

You can clearly see the deck is bent so much that the thin webbing on the hole below has stretched and popped from the overloading done by the forklifts.

This wasn’t just wear and tear — it was the result of bad product specification. Instead of recommending a scale built for heavy forklift traffic, the previous provider had sold the cheapest model that would barely last beyond the warranty period.

Calibration Test and Results

Once we cleaned the pit and reinstalled the scale, we loaded 900 lbs of NIST-traceable test weights. The scale read 872 lbs, an unacceptable error.

We attempted an electronic adjustment but found a zero shift of over 700 lbs since the last calibration — a clear indicator of sensor overload and damage.

The device ultimately failed inspection due to multiple damaged load cells and deformed structural components. Our professional recommendation: full scale replacement.

Why This Matters for Your Business

Accurate scales are essential for compliance, safety, and cost control. Using an underrated or poorly maintained scale can lead to:

- Inaccurate billing and inventory records

- Compliance violations and failed audits

- Expensive repairs or full replacement sooner than expected

Get Honest, Professional Scale Service

This customer appreciated our thorough inspection and honest advice — a level of support they weren’t getting from their previous provider.

If you suspect your scales aren’t being serviced properly, contact Peninsula Scale today.

We’ll keep your service provider honest and give you a clear, unbiased recommendation for your facility.