The Hidden Cost of Inexpensive Overseas Equipment

In today’s global economy, competition has made it possible to purchase weighing equipment from all over the world — often at a lower cost. While that’s good for budgets upfront, the hidden costs often appear when routine maintenance or repairs are needed.

The Customer’s Calibration Challenge

Recently, we were called to a facility in Orlando, Florida where a scale mounting bolt had loosened and damaged the single point load cell. The mounting bolt tore through the potting compound at the bottom of the cell, damaging the fine wires that connect to the strain gauges.

The customer’s maintenance staff ordered a replacement load cell and installed it — not realizing that load cells are analog sensors and cannot be swapped out like digital sensors.

The Consequences of Incorrect Installation

Because the load cell was not properly calibrated, the customer had to adjust their expanding foam production process repeatedly just to keep block densities close to specification.

When they contacted us for help, we followed our standard protocol:

- Ask for the make and model of the device.

- Advise the customer to obtain the manufacturer’s official calibration procedure before we arrive.

Unfortunately, because the manufacturer was overseas, getting this documentation took weeks of requests and scheduling. They ultimately had to wait for an overseas engineer to be onsite for unrelated work before we could proceed.

What We Found During Inspection

Working alongside the visiting engineer, we discovered:

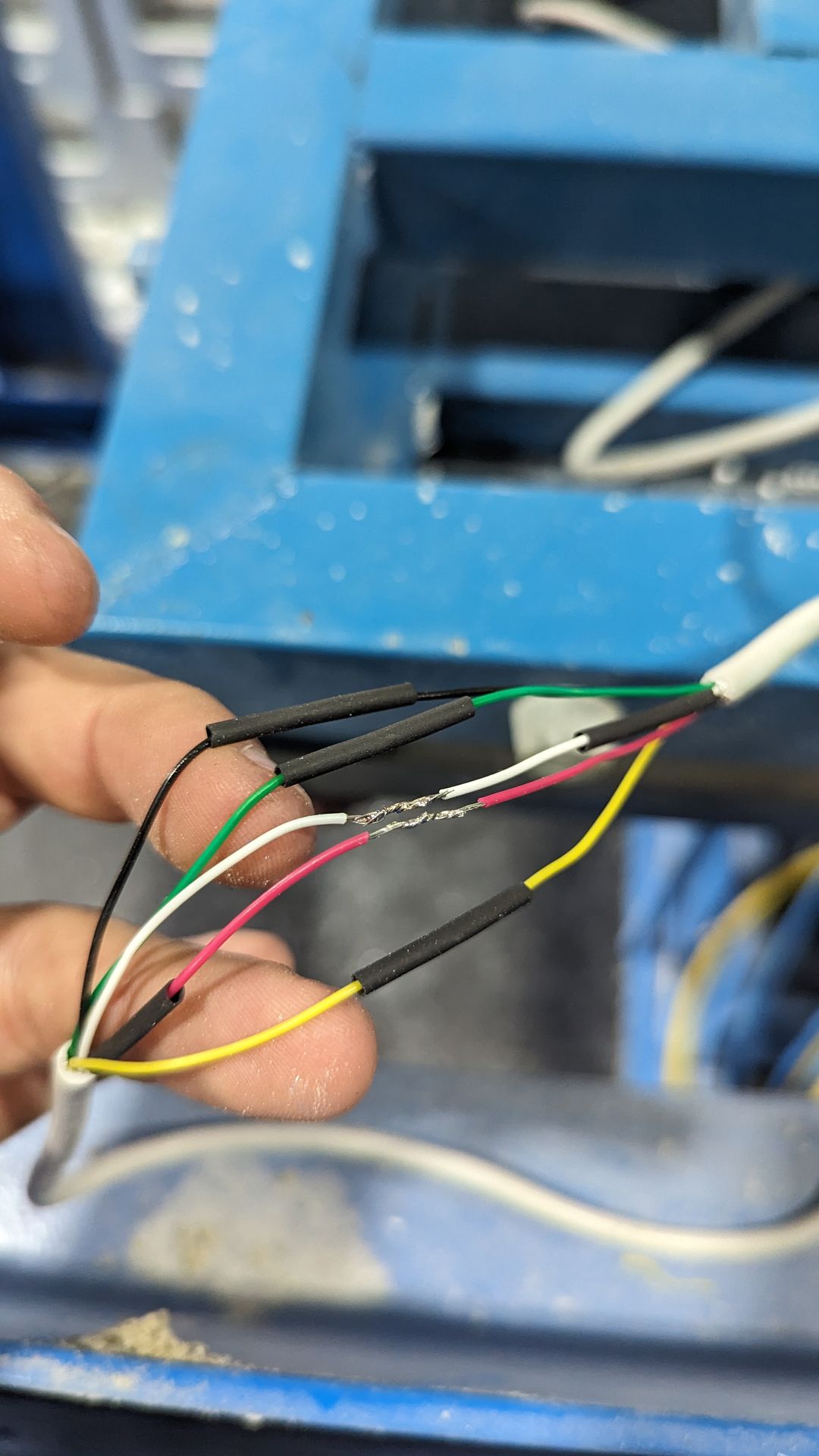

- The replacement load cell had signal wires swapped, causing the scale to read negative weight when load was applied.

- The device had no standard terminal blocks, and connections were potted directly to the board, making proper servicing difficult.

To fix the issue, we re-soldered the connections using glue-lined heat shrink to ensure durability. Once the manufacturer’s documentation was translated into English, we applied NIST-certified test weights and performed a proper recalibration.

The Cost of Limited Support

What should have been a two-hour service call turned into multiple visits, scheduling delays, and higher costs.

The lesson?

If the equipment had been manufactured or fully supported in North America, with English-language documentation readily available, the repair could have been completed quickly and cost-effectively.

Our Recommendation

When investing in weighing equipment:

- Choose devices with clear, accessible calibration procedures.

- Ensure the manufacturer offers domestic support and parts availability.

- Ensure that Avoirdupois (pounds instead of kilogram) weights can be used as kilogram weights are much less common in North America and are not always carried in large quantities unless specified before arrival

- Factor in lifetime serviceability, not just the purchase price.

Contact Peninsula Scale for recommendations on industrial weighing equipment that’s supported here in North America, so you can avoid costly downtime and unnecessary headaches.